Thread guides are essential components in sewing machines that direct the thread through the machine, ensuring smooth operation and consistent stitching. Proper threading is crucial for avoiding jams, maintaining stitch quality, and preventing thread breakage. Understanding how to use thread guides effectively can significantly improve your sewing experience and project outcomes. Regular maintenance and correct threading techniques are vital for optimal performance.

1.1 What is a Thread Guide?

A thread guide is a mechanism in sewing machines that directs the thread through the machine, ensuring proper tension and alignment. It plays a crucial role in maintaining consistent stitch quality and preventing thread-related issues like jams or breakage. Proper use and maintenance of thread guides are essential for smooth fabric handling and overall sewing performance.

1.2 Importance of Thread Guides in Sewing

Thread guides are vital for ensuring smooth thread flow, maintaining consistent tension, and preventing jams or breakage. They help achieve even stitching, reduce fabric puckering, and minimize thread waste. Properly functioning thread guides enhance sewing efficiency, especially when working with delicate or heavy fabrics, making them indispensable for both beginners and experienced sewists to achieve professional-grade results.

Types of Thread Guides in Sewing Machines

Thread guides in sewing machines come in various forms, including built-in, attachable, and specialized designs for different fabrics. Each type ensures proper thread flow and tension control.

2.1 Built-In Thread Guides

Built-in thread guides are integrated into the sewing machine’s design, providing a fixed path for the thread. They are typically metal or plastic and are designed for specific thread types. These guides minimize manual adjustments, ensuring consistent thread flow and tension. Regular cleaning is essential to prevent thread jams and maintain smooth operation. Proper use extends machine longevity and enhances stitching quality. Effective for most fabrics, they are a reliable choice for seamless sewing experiences.

2.2 Attachable Thread Guides

Attachable thread guides are optional accessories designed to enhance threading precision. Made from durable materials like plastic or metal, they can be added or removed as needed. These guides are ideal for managing specialty threads, such as metallic or embroidery floss, and can be adjusted for different fabric types. They reduce thread tangling and improve stitch consistency, offering flexibility for diverse sewing projects. Regularly cleaning them ensures optimal performance and thread flow.

2.3 Specialized Thread Guides for Different Fabrics

Specialized thread guides are designed for specific fabrics, ensuring optimal thread flow and stitch quality. For delicate fabrics like silk, guides with smooth surfaces prevent thread damage. Heavy-duty guides for thick materials like denim or canvas maintain tension and reduce thread breakage. Adjusting guides for stretchy fabrics like knit ensures even stretch and prevents distortion. Customizing guides for fabric type enhances sewing accuracy and efficiency, minimizing jams and inconsistencies.

How to Properly Thread a Sewing Machine

Properly threading a sewing machine ensures smooth operation and consistent stitching. Follow the machine’s manual, use the thread guide, and maintain the correct tension to prevent jams and ensure quality results.

3.1 Step-by-Step Guide to Threading

Begin by turning off the machine and locating the spool pin. Place the thread on the pin and guide it through the tension discs. Follow the machine’s path, looping the thread around each guide. Insert the thread into the needle’s eye, gently pulling to seat it. Ensure the thread is taut but not overly tight to maintain proper tension for smooth stitching.

3.2 Common Mistakes to Avoid

Common mistakes when threading include not following the machine’s thread path, leading to jams and tangles. Forgetting to properly seat the thread results in loose stitches. Incorrect thread tension negatively impacts stitch quality. Ignoring the appropriate thread type for fabric causes breakage. Avoiding these errors leads to smoother, more professional sewing experiences and better results.

Understanding Thread Tension and Its Role

Thread tension controls the tightness of the thread, impacting stitch quality and fabric behavior. Proper tension ensures even stitching, while incorrect settings can cause puckering or loose threads. Adjusting tension balances the thread’s flow, crucial for consistent sewing results across various fabrics and projects.

4.1 How Thread Tension Affects Stitch Quality

Thread tension significantly impacts stitch quality by controlling the thread’s tightness. Proper tension ensures balanced stitches, while uneven tension can cause puckering, loose threads, or uneven fabric lay. Incorrect settings may lead to thread breakage or misalignment, especially on delicate or heavy fabrics. Adjusting tension is crucial for achieving consistent, professional-looking results in sewing projects.

4.2 Adjusting Thread Tension for Different Fabrics

Adjusting thread tension is crucial for achieving optimal stitch quality across various fabrics. Start by setting the tension to medium, then test it by sewing a straight line. For heavy fabrics like denim, a slightly looser tension prevents thread breakage and puckering. Delicate fabrics such as silk may require a tighter tension to avoid loose stitches and fabric slippage. Knits need a balanced tension to accommodate their stretch without causing runs. Consider the thread type as well; thicker threads may need more tension, while thinner threads require less. If the thread breaks frequently, it may indicate tension that’s too tight, whereas uneven stitches suggest the need for adjustment. Regular machine maintenance, including cleaning and lubrication, ensures smooth thread flow and consistent tension. By understanding fabric weight, texture, and thread compatibility, you can fine-tune tension settings for professional-looking results. Trial and error may be necessary to find the perfect balance for each fabric and project.

Tips for Using Thread Guides Effectively

Always use the correct thread type for your fabric and ensure proper alignment. Clean guides regularly to prevent thread buildup and jams. Adjust tension as needed for smooth stitching and consistent results. Proper threading techniques and regular machine maintenance are key to optimal performance and durability.

5.1 Choosing the Right Thread for Your Project

Selecting the appropriate thread for your sewing project is crucial for optimal results. Consider the fabric type, thread weight, and fiber content to ensure compatibility. Matching thread color to fabric enhances seam invisibility. Always consult your sewing machine’s manual for thread recommendations. Testing thread samples on scrap fabric can prevent issues like breakage or uneven stitching during your project.

5.2 Maintaining Proper Thread Flow

Maintaining proper thread flow ensures smooth stitching and prevents machine jams. Keep the thread spool upright and avoid over-tightening the spool cap. Regularly clean the thread guides and tension discs to remove lint. Use the correct thread path and maintain consistent tension to prevent tangles or breakage. Proper thread flow is key to efficient and high-quality sewing results every time.

Common Issues with Thread Guides

Common issues with thread guides include thread jamming and misalignment, which can disrupt stitching and sewing efficiency. Regular maintenance and proper threading techniques help prevent these problems.

6.1 Thread Jamming and How to Prevent It

Thread jamming is a common issue that disrupts sewing efficiency. It often occurs due to incorrect threading, loose tension, or debris buildup. To prevent jams, ensure the machine is threaded correctly, maintain consistent tension, and regularly clean the thread guides and bobbin area. Using high-quality thread and avoiding overloading the bobbin can also minimize such issues.

6.2 Misaligned or Damaged Thread Guides

Misaligned or damaged thread guides can disrupt thread flow, leading to uneven stitches or machine malfunction. Regular inspection is crucial to identify wear or misalignment. Proper realignment or replacement of guides ensures smooth thread movement and consistent stitching. Always refer to the machine’s manual for guidance on adjusting or replacing thread guides to maintain optimal sewing performance.

Maintenance and Cleaning of Thread Guides

Regular cleaning of thread guides removes lint and debris, ensuring smooth thread flow. Use a brush or compressed air for effective maintenance and to prevent jams.

7.1 Regular Cleaning Practices

Regularly clean thread guides with a soft brush or compressed air to remove lint and debris. This prevents thread jams and ensures smooth operation. Use a cotton swab for tight spaces. Avoid harsh chemicals, as they may damage the guides. Cleaning after each project helps maintain optimal performance and extends the machine’s lifespan.

7.2 Lubrication and Upkeep Tips

Regularly lubricate moving parts of your sewing machine with high-quality sewing machine oil to ensure smooth operation. Apply a few drops to the bobbin area and tension discs, but avoid over-lubricating. Check for worn or misaligned thread guides and replace them promptly. Use a clean cloth to wipe excess oil and debris. Proper upkeep prevents friction and extends the machine’s lifespan.

Selecting the Right Thread for Your Sewing Machine

Choose thread that matches your fabric type and stitch requirements. Consider thread weight, fiber content, and color for optimal compatibility. Proper thread selection ensures smooth sewing and durability.

8.1 Factors to Consider When Choosing Thread

When selecting thread, consider fabric type, weight, and fiber content. Match thread color to your project for consistency. Thread weight impacts seam strength, while fiber type affects durability and stretch. Ensure thread compatibility with your machine’s tension settings. Proper thread choice ensures smooth stitching, prevents breakage, and enhances overall fabric integrity. Always test thread before starting your project.

8.2 Thread Weight and Its Impact on Sewing

Thread weight, measured in deniers or tex, affects stitching quality and fabric compatibility. Heavier threads (higher denier) suit thick fabrics like denim, while lighter threads (lower denier) are ideal for delicate materials like silk. Incorrect thread weight can cause uneven stitches or fabric damage. Choosing the right weight ensures optimal seam strength and prevents thread breakage during sewing.

Advanced Techniques for Using Thread Guides

Advanced techniques involve using dual threads for heavy-duty sewing and adjusting guides for embroidery. These methods enhance stitch quality and allow for intricate designs on various fabrics.

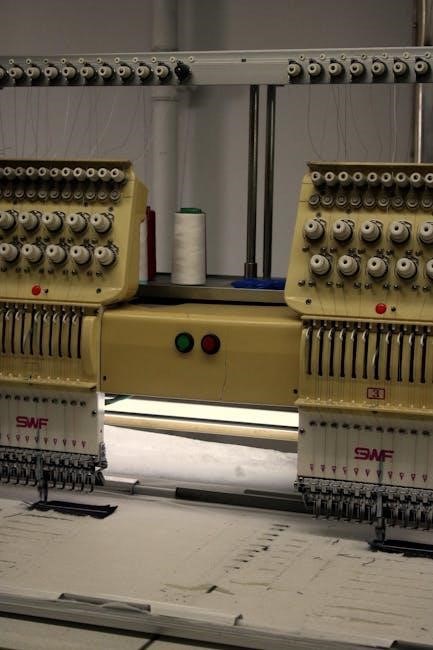

9.1 Using Dual Threads for Heavy-Duty Sewing

Dual threads are ideal for heavy-duty sewing, offering enhanced strength and durability. By using two threads, you can handle thick fabrics like denim or canvas with ease, ensuring consistent stitching and reducing breakage. This technique is particularly useful for industrial or heavy-duty projects, providing a professional finish and extending the life of your sewing machine.

9.2 Thread Guide Adjustments for Embroidery

For embroidery, precise thread guide adjustments are crucial to ensure smooth stitching and intricate designs. Proper tension settings and thread alignment prevent breakage and misalignment. Using specialized embroidery threads and adjusting the guide to accommodate their thickness enhances stitch quality. Regular cleaning and lubrication of the thread guide further optimize performance, ensuring vibrant and precise embroidery patterns every time.

Troubleshooting Common Thread-Related Problems

Common issues include thread jamming, breakage, and uneven stitching. Check thread tension, clear jams promptly, and ensure proper thread guide alignment for smooth operation and consistent results.

10.1 Identifying and Solving Thread Breakage Issues

Thread breakage often occurs due to improper threading, incorrect tension, or using the wrong thread type. To resolve, check thread guides for misalignment, ensure proper tension adjustment, and use high-quality thread suitable for your fabric. Regularly cleaning and lubricating the machine can also prevent frequent breakages and maintain smooth operation.

10.2 Fixing Uneven Stitching Caused by Thread Misalignment

Uneven stitching often stems from thread misalignment. Ensure the thread is correctly seated in all guides and tension is balanced. Using the right thread type for your fabric is crucial. Rethreading the machine and maintaining proper thread flow can resolve the issue, ensuring consistent stitch quality and preventing further misalignment problems.

The Future of Thread Guides in Sewing Machines

The future of thread guides in sewing machines lies in innovations like automatic threading systems and AI-driven adjustments, enhancing efficiency and precision for sewists of all skill levels.

11.1 Innovations in Thread Guide Technology

Innovations in thread guide technology are revolutionizing sewing machines with automatic threading systems and AI-driven adjustments. Smart sensors now detect thread type and tension, optimizing stitching automatically. Advanced guides minimize jams and ensure precise thread flow. These cutting-edge features enhance sewing efficiency, reduce errors, and cater to both casual and industrial users, promising a future of seamless and intelligent sewing experiences.

11.2 Automatic Thread Guides in Modern Machines

Modern sewing machines feature automatic thread guides that streamline the threading process, reducing manual effort and errors. These systems use sensors to detect thread placement and tension, adjusting automatically for optimal stitching. Automatic guides minimize thread jams, ensure consistent stitch quality, and enhance overall efficiency, making sewing more accessible and user-friendly for both beginners and experienced sewists alike every time.

Mastery of thread guides enhances sewing efficiency and quality. Proper use and maintenance ensure smooth operation, reducing errors and extending machine longevity for optimal sewing outcomes every time.

12.1 Summary of Key Points

Thread guides are vital for smooth threading, preventing jams, and ensuring even tension. Proper use enhances stitch quality, reduces breakage, and extends machine longevity. Regular maintenance, correct threading techniques, and choosing the right thread type are essential for optimal performance. Understanding thread guides and their care can significantly improve sewing efficiency and overall results, making them indispensable for both beginners and experienced sewists alike.

12.2 Final Tips for Mastering Thread Guides

Regularly clean and maintain thread guides to ensure smooth operation. Always thread the machine correctly, following the manual. Use the right thread type for your fabric. Check guides for damage and replace if necessary. Keep thread tension balanced for consistent stitching. Practice threading techniques to build confidence and efficiency in your sewing projects.